Features and Benefits

Neat arrangement and ergonomically designed control

| • |

Simple operation by 6 individual push buttons for 8 motion sequences |

| • |

2 separate potentiometers for variable clamping force 300 / 500 – 2200 daN (kg) are standard |

| • |

3 Pressing velocities and adjustment rates

5 /10 / 25 mm/sec. (with fine positioning / creep feed) |

| • |

Adjustable clamping cycle time 0-30 min. (changeable to seconds and hours) with electronical automatic opening |

| • |

Large green light signal to inform the machine operator about the state of the control/machine |

|

|

| • |

Simple operation by electronic controller with LCD display and transparency-protected keyboard |

| • |

Variable clamping force 600 / 800 – 3500 daN (kg) separate for vertical and horizontal pressing beam |

| • |

Main and Pre-Pressure input with electronic pressure monitoring |

| • |

Pressing velocities 5-10 mm/sec. automatic controlled according the pressing force |

| • |

Adjustemten rate with 50 mm/sec. with sensors for automatic case goods recognition in both lamellar clamping beams (standard) can be deactivated for special case goods |

| • |

13 motion sequences can be selected via the control:

6 for manual opening and closing

7 for automatic cycles

(V / H / VH / VVH / VVVH / HHV / HHHV) |

| • |

Clamping time pre-selection with automatic opening / item counter / self- diagnostics |

| • |

Light signals inform the machine operator about the state of the control/machine |

|

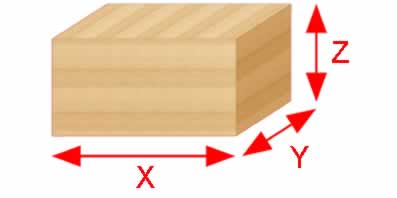

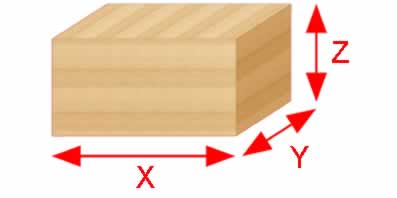

Working dimensions

| Concept Eco |

|

Concept Primus |

| • |

Width (X): 150 – 2500 mm |

| • |

Height (Z): 150 – 1300 mm |

| • |

Depth (Y): 150 – 700 mm |

|

|

| • |

Width (X): 150 – 2500 mm |

| • |

Height (Z): 150 – 1300 mm |

| • |

Depth (Y): 150 – 700 mm

= Concept Primus 70 |

| • |

Depth (Y): 150 – 900 mm

= Concept Primus 90 |

|

Special working dimensions on request,

like e.g. a witdh (X) of 3000 mm. |

|

|

Pressing of several case goods

Several case goods or drawers can be pressed at the same time.

Clamping of cabinets with 45 degree mitres

The clamping of cabinets with 45 degree mitres can be performed with the use of 4 pcs. hardwood corner blocks (optional) or with use of fine positioning. Useable at Concept Eco and Concept Primus.

Clamping of cabinets with over-lapping tops

The clamping of cabinets with over-lapping tops can be performed with the use of hardwood blocks (optional). Useable at Concept Eco and Concept Primus.

Additonal advantages that will make work easier, reduce set-up time and increase precision, we will explain to you in a personal conversation

Please enter your details below to download the brochure