MAYER PS 80

Panel Saw 3200 x 3200

MAYER, the German company has been producing Panel Cutting Saws for cutting wood based material, plastic material and nonferrous metal since more than 50 years. Machines from 80 to 255 mm cutting height are offered. With saw motors from 9 to 75 KW and with a cutting length from 1200 to 9000 mm. Single axis machines with manual loading and fully automatic angular systems are produced. Mayer-known quality in terms of sturdiness and reliability has been coupled with modern design. The ergonomic control panel and intuitive software make operating the machine easy and reliable The machines are characterized by a very sturdy construction, high precision and accuracy of cut.

The PS 80 STANDARD

is the perfect start into professional panel-sizing and sets standards in the compact class for horizontal panel saws.

In detail matured constructions, careful working, highest precision and most modern design gives this machine the special touch.

Basic machine:

- Feed speed infinitely variable from 5 – 100 m/min. return speed approx. 130 m/min.

- Dust channel left hand side for connection to dust extraction plant diam. 120 mm

- Saw carriage travels on rounded guides.

- Fast and jerk free travelling speed because saw carriage is driven by rack and pinion (no chain).

- Adjustment of cutting length by laser sensor

- Slotted clamping beam for dividing the panels without residual parts

- Transparent segment safety guard (flap lamellas) enables the operating personal the view on the cutting line

- Quick changing unit for main and scoring saw

- Manual cutting height adjustment – 2 steps

- Control console turn able

- Machine is CE certified and dust proofed

Specification:

Saw motor 9 KW

Saw blade dia. max. 320 mm

Saw blade projection max. 80 mm

Length of cut 3200 mm

Working height 1000 mm

Dust suction air volume 3000 m3/h

Voltage 3 x 415 V / 50 Hz

02 18021

SCORING AGGREGATE 1,1 KW, FOR SAWBLADE 150 MM

Scoring aggregate pneumatically lowering in return, scoring motor 1,1 KW

(1,5 hp), for scoring saw blade 150 mm dia, con.

03 18031

CROSS CUT TABLE – 2000 x 600 AIR FLOATATION

Cross cut table in air floatation construction on the left to the

front, 2000 x 600 mm. with infeed roller at the front side and

strong cross cutting rail 2000 mm long, behind cutting 650 mm.

04 18131

ADDITIONAL FRONT TABLE – AIR FLOATATION

to front in air floatation construction

2 pcs, size 2000 x 600 mm

05 03 -18041

MATERIAL PUSHER

TRAVELLING WAY 3200 mm

Bilaterally guided material pusher, driven by rack and pinion and

AC servo motor, advance 25 m/min, return speed 80 m/min.

separate and contact free magnetic measuring system,

rear supporting table consisting of 9 double roller tracks.

Cutting length and travelling way 3200

06 18112

CLAMPING DEVICES AT THE MATERIAL PUSHER

Single finger system,

opening height 75 mm.

6 clamps

07 18141

SIDE PRESSURE UNIT BEHIND THE CLAMPING BEAM

fully automatic adjustment, working area from 20 to 1200 mm

08 14077

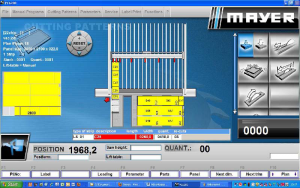

ELECTRONIC CONTROL – PC6200

Modular constructed control system with 19” TFT Flatscreen.

A PC with the latest specification is used. Operating system:

Windows 7. The control is prepared for an online connection

and for the connection of a label printer. The control can be easily

connected to a local network. The data input is reduced to a minimum

and therefore very easy. The trim cut for example is calculated

automatically and there is the possibility of an edge correction.

The actual residual dimension in length and width direction is always

indicated during the input so that the operator must not make any

calculations. During working the cutting sequence is shown (moving

pictures). Through it you can always see which component is being

worked and how the parts have to be put into the machine. The

following keys are mounted at the cross cut table:

- closing of package clamps

- automatic trimming

- emergency stop

09 Saw blades:

1 TCT SAW BLADE , 320 x 4,4 x 30 MM, 60 TEETH

1 TCT SAW MAIN BLADE , 355 x 4,4 x 30 MM, 72 TEETH

1 TCT SCORING SAW BLADE, 150 MM DIA., 28 TEETH

INCLUDED OPTIONS:

10 14073

OPTIMIZATION PROGRAM EASY OPTIMIZER

integrated in the control. Only the component description, the component

dimensions with number of pieces and if existing the veneer direction

have to be entered. Then the program produces automatically the cutting

plans. The effort to enter data is reduced to a minimum. As the optimization

is executed at the machine, there is no problem with the offcuts. They can

be used immediately for the next optimization run.

11 18752

AUTOMATIC CUTTING HEIGHT ADJUSTMENT BY MOTOR

for the saw blade. Lifting and lowering of the saw blade by means of

positioning motor. The pack height is measured by special measuring

system. Because of this a constant Blade projection is achieved independent

from the pack height and the saw blade diameter. This unit can also be used

for grooving. The depth of the grooves can be entered at the control. Each

groove can have different dimensions.

13 14082

AIR CONDITION

For switch cabinet