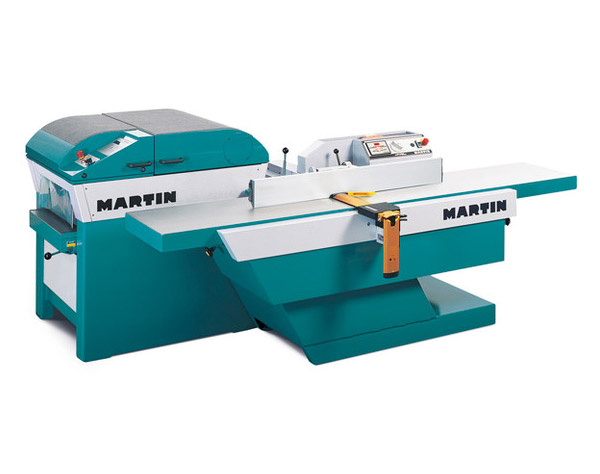

MARTIN T54

The T54: A jointer that fits your workshop.

Perfect end results can only be obtained with perfect joints. Therefore the T54 offers the ideal conditions to create an optimum basis.

The fence runs smoothly and without tilting on ball bearing guided courses – as precise years later as on the very first day.

Perfect results in no time at all

Perfect end results can only be obtained with perfectly jointed material. The T54 offers the ideal conditions to create unequalled precision. The SMOOTH-RUNNING FENCE with INTEGRATED AUXILIARY FENCE enables quick and precise jointing operations. The fence runs smoothly and without tilting on ball bearing guided courses – as precise years later as on the very first day. Chamfers can also be machined in a flash, because any ANGLE BETWEEN 90° UND 45° can be set quickly with the manually operated controls.

Everything down to preference

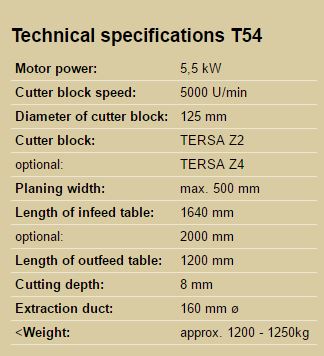

The quick and precise setting for the depth of the cut between 0-8 mm is actuated electrically with a clear, easy to read scale. The centralized control panel features depth of cut setting and the start button for the cutting spindle. The optional T544 fence top mounted control console offers even more comfort to the operator, allowing the controls to ride in and out with the fence, keeping them easily in reach. The digital depth of cut display has a resolution of 0,1 mm.

Safety comes as standard

It does not matter whether you are face jointing or edge jointing, the modern SUVA jointer guard is a quick and safe safety device that has become standard equipment in European shops. An auxiliary fence is integrated into the main jointer fence so that small, narrow workpieces can also be fed safely over the machine table. Furthermore, a mount for a power feeder also comes as standard equipment. The T54 comes complete with an automatic star-delta starter connection and a wear free electronic brake.

The best conditions for perfect results

The two-knife TERSA solid steel cutterhead on the T54 offers many practical advantages: The smoothness in the precision bearings and the exact positioning of the positive fitting, reversible TERSA knives results in one of the most extremely accurate cutting circles obtainable, thereby resulting in a smooth and accurate planed finish. The TERSA reversible knives are available in four different types (chrome steel, HSS, M42 and carbide). The cutterhead can also be supplied in a four-knife configuration as well. As always, CHANGING THE TERSA KNIVES takes less than a minute per blade.

Clever combination saves space

Clever combination saves space Unlike combination machines, the MARTIN T45 and T54 function without the need for timeconsuming changes and, thanks to the spacesaving installation, both of the machines fit together in small footprint. In contrast to the combination machines, both MARTINs can also be operated at the same time and because of their close proximity to one another, they can even be operated by one person. The dust collection ports can be attached to either the left or right-hand side of the T45, allowing you to optimize your dust collection system without restricting material and work flow within your facility. Of course, both T45 Contour machines can also be combined with the T54 for a perfect „planing and profiling center“. You can create unique possibilities with this duo, going far beyond the combinations that have been familiar to our industry so far.